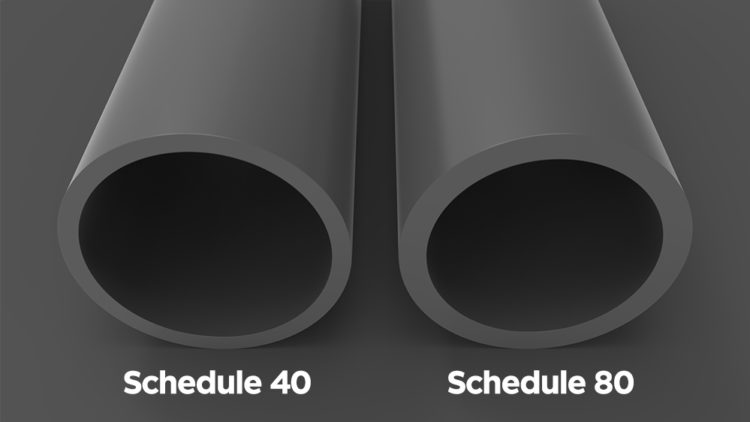

The major difference between schedule 40 and schedule 80 pipe is the wall thickness, inside diameter, and their weight. Schedule 80 will have a greater wall thickness, a smaller inside diameter and a higher weight than Schedule 40 pipe at a given nominal pipe size.

But for the different schedules the internal diameter is the same, so the thinner sidewall of schedule 30 leaves you with a smaller outside diameter. Since nearly all the schedule 40 fittings we use glue to the outside, they won’t work.

Thereof, What is Schedule 80 PVC pipe used for?

Because schedule 80 PVC is a thicker pipe, it is usually is used for applications that are commercial or industrial in nature. These more demanding applications generally require piping that will stand up to high pressures and harsh environments.

Also to know is, Can you drive over Schedule 40 PVC? Re: Driving over Schedule 40 PVC With little pipes, a foot of dirt over it will carry anything you can drive over it if the soil has been compacted after filling the trench. If the soil is new, and loose, then it doesn’t do anything to carry the load and the pipe may be damaged from movement.

Subsequently, question is, How much weight can schedule 40 plastic PVC take? 954 pounds

Also, What is Schedule 40 PVC pipe used for?

PVC Schedule 40 pipe is used for drainage and lower pressure water flow applications. Schedule 40 PVC pipe can handle up to 140 degrees F in temperature. Pipe lengths come in standard 10′ or 20′ sections.

Can PVC hold weight?

PVC pipe tensile strength can be measured by hanging weight from the pipe until it bends or cracks. … 8″ PVC pipe of either schedule is extremely strong for how inexpensive it is. The smaller sizes are exponentially weaker, but can still hold a great deal of weight if they must.

Is Schedule 80 PVC stronger than Schedule 40?

Schedule 80 pipe is designed with a thicker wall. This means the pipe is thicker and stronger, and as a result it can handle higher pressures. … Schedule 40 PVC pipe is strong, rigid, and can handle pressure applications. For jobs that require a higher pressurization though, schedule 80 pipe is better suited.

Can Schedule 80 PVC be glued to schedule 40?

Because schedule 40 PVC and schedule 80 PVC pipe have the same outer diameter, you can use schedule 40 PVC fittings with schedule 80 PVC pipe and vice versa.

How much weight can a PVC pipe hold?

As per estimation, schedule 40 1.5 inch diameter PVC pipe can take 954 pounds of tensile strength, and schedule 80 1.5 inch diameter PVC pipe can take 1225 pounds of tensile strength. Tensile strength is simply the most weight that can be put on something before it breaks.

Is PVC pipe sturdy?

PVC Pipes are strong and durable despite their relatively low weight. This makes PVC Pipes suitable for all types of long-term applications including domestic water, sewerage, stormwater, and deep underground piping systems.

Is Schedule 80 PVC chemical resistant?

PVC is highly resistant to acids, alkalis, alcohols, and many other corrosive materials. …

Can you mix Schedule 40 and 80 PVC?

The increased wall thickness of schedule 80 PVC is necessary in some applications. … Even though it is possible to combine schedule 80 and schedule 40 PVC together it is not recommended. This is because the changing internal diameter can cause friction or uneven flow.

What does Schedule 80 PVC mean?

PVC pipe is connected by fittings such as this elbow. Schedule 80 PVC pipe denotes PVC pipe of a standard wall thickness. … No matter what schedule of pipe is used, the outside diameter is standard and the inside diameter decreases as the schedule increases.

What is the tensile strength of PVC?

Property Value

——————————— —————————————————————————————-

Melt Temperature 212 – 500 °F (100 – 260°C) ***

Heat Deflection Temperature (HDT) 92 °C (198 °F) **

Tensile Strength Flexible PVC: 6.9 – 25 MPa (1000 – 3625 PSI) Rigid PVC: 34 – 62 MPa (4930 – 9000 PSI) **

Specific Gravity 1.35 – 1.45

How much weight can PVC hold?

As per estimation, schedule 40 1.5 inch diameter PVC pipe can take 954 pounds of tensile strength, and schedule 80 1.5 inch diameter PVC pipe can take 1225 pounds of tensile strength. Tensile strength is simply the most weight that can be put on something before it breaks.

How strong is Schedule 40 PVC?

The amount of pressure a pipe is rated for varies based on size, but a 4” schedule 80 PVC pipe for instance is rated at 320 PSI while a schedule 40 PVC pipe of the same size is only rated at 220 PSI. You can find schedule 80 pipe used most often in heavy duty commercial and industrial applications.

What is the difference between Schedule 20 and Schedule 40 in the PVC pipe?

SCHEDULE 20 PVC PIPE The wall of the pipe is much lighter than that of Schedule 40, and must only be used in situations where vehicles, traffic, or any other type of equipment crossing the area will not be a factor. The outside diameter is the same as SDR 35, and is compatible with all Schedule 20 and SDR 35 fittings.

Don’t forget to share this post 💖

References and Further Readings :