Pop rivets, also known as blind rivets, are a type of rivet. They are used in applications where there is limited – or no – access to the rear side (blind side) of the parts to be joined.

– Head Style Types. These consist of large flange, countersunk and dome varieties. …

– Structural Types. These consist of the open end, closed end and T-rivet types. …

– Grooved, Easy Entry and High Strength Rivet Types. Grooved rivets are designed to be fitted in a hole of soft, fibrous materials such as wood, cork or cardboard.

Thereof, What are the differences between fitting a solid rivet and fitting a blind rivet?

The setting of these fasteners requires access to both sides of a structure. Solid rivets are driven using a hydraulically, pneumatically, or electromagnetically actuated squeezing tool or even a handheld hammer. Applications where only one side is accessible require “blind” rivets.

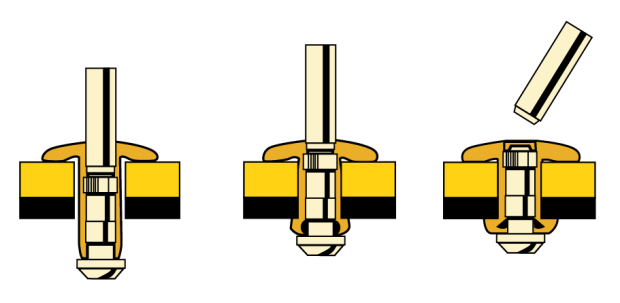

Also to know is, What is a rivet mandrel? Rivets have a two-piece construction; one is called the rivet body, shell, or hat and another is called the stem or mandrel. Both the hat and mandrel are pre-assembled and ready to use. Rivets are installed by using a riveting tool to draw the mandrel which causes the body to deform and clamp down on the joint.

Subsequently, question is, What materials does a pop rivet work with? A wide variety of materials and platings are available, most common base metals are steel, brass, copper, stainless, aluminum and most common platings are zinc, nickel, brass, tin. Tubular rivets are normally waxed to facilitate proper assembly.

Also, How do you put a pop rivet in?

What sizes do pop rivets come in?

– The diameter sizes available for blind rivets are:

– Metric series – 2.4, 3, 3.2, 4, 4.8, 5, 6.4 and 7.4mm.

– Inch series – 3/32, 1/8, 5/32, 3/16, 1/4 and 19/64″.

How do you know what size blind rivet to buy?

The length of the rivet should be equal to the thickness of both objects you are fastening, plus 1.5 times the diameter of the rivet’s stem.

Can you rivet a blind hole?

Fastening in a Blind Hole Blind rivets may be set in a blind hole or milled slot. The success of this depends on the material of the parts to be riveted and the material of the rivet. Testing will be required.

What is a blind rivet used for?

Blind rivets, also commonly referred to as POP Rivets, are mainly used in applications where there is no access to the rear (blind side) of the joint. Rivets have a two-piece construction; one is called the rivet body, shell, or hat and another is called the stem or mandrel.

How are blind rivets installed?

Comprised of a rivet and an integrated mandrel, blind rivets are installed in a tight hole that passes through whatever material you’re riveting. A riveter is then used to pull the mandrel back while holding the rivet in place.

Are blind rivets waterproof?

The CUP sealed blind rivets are made of 316 stainless steel for the body and the mandrel from 318L Duplex and tested to demonstrate 100% waterproof.

Do blind rivets leak?

Blind rivets, unlike threaded fasteners, avoid problems of over or undertorquing, and stripping. Rivets also won’t loosen once installed because the rivet body is as large or larger than the hole it’s put in. They also won’t shake out or break off, and the tight seal helps prevent leaks and seepage.

Are pop rivets and blind rivets the same?

Blind rivets, also commonly referred to as POP Rivets, are mainly used in applications where there is no access to the rear (blind side) of the joint. Rivets have a two-piece construction; one is called the rivet body, shell, or hat and another is called the stem or mandrel.

What are the three types of rivets?

There are four basic types of rivets; tubular, blind, solid and split.

What is blind rivet?

Blind rivets, a.k.a. break stem rivets, are tubular fasteners with a mandrel through the center. Blind rivets are inserted into drilled holes in the parts to be joined, and a special tool is used to draw the mandrel through the body of the rivet. The blind end expands, and the mandrel is snapped off.

Can blind rivets be plastic?

These blind rivets feature domed heads and plastic body construction. They can be fully installed in a joint on just one side of a structure, where it is “blind” to the opposing side.

What are the strongest pop rivets?

Also, aluminum rivets with aluminum mandrels are the least strong; aluminum rivets with steel mandrels are stronger; steel rivets with steel mandrels are stronger still; and stainless steel rivets with either steel or stainless steel mandrels are the strongest.

Don’t forget to share this post 💖

References and Further Readings :