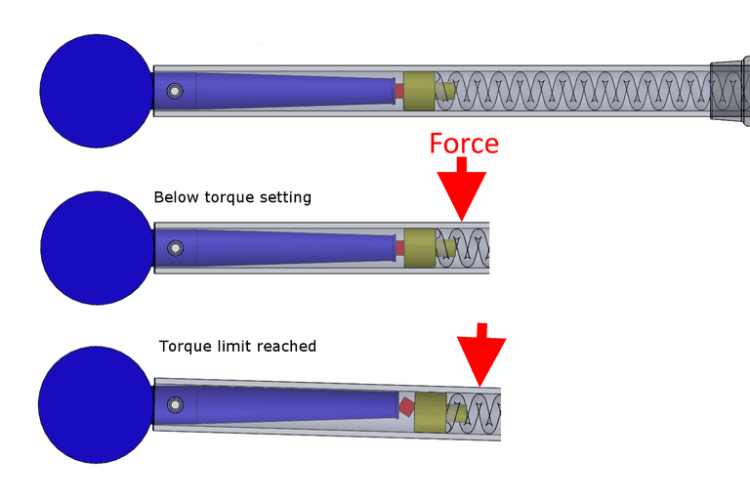

When a clicker wrench is pulled to the point of the torque setting, the lever inside the wrench rolls over a cam and hits the inside of the wrench handle wall. This effect makes the “click” sound, and tells the operator that they have reached the desired torque value.

Thereof, Why does my torque wrench not click?

Test it with a bolt thats already tight, but set the wrench lower than the bolt should be tightened to to make sure it still clicks. If it doesn’t click before the bolt turns, it likely needs to be opened up to re-position the bearing.

Also to know is, How do you calibrate a click torque wrench?

Subsequently, question is, How do you calibrate a inch pound torque wrench? To obtain the correct setting for your torque wrench, you will need to multiply the distance from step one by whatever weight you will be using to get the inch-pounds. (For this example, we will use a 20-pound weight.) Then divide that number by 12, which will give you the foot-pounds.

Also, What is the working of torque wrench why this is used?

What is a torque wrench ? A torque wrench is a tool used to control and apply a specific torque to a fastener such as a bolt or a nut. It is a fundamental element in general mechanics, tire changing operations and industrial maintenance & repair industries, to ensure customers’ safety.

What should be periodically checked on a torque wrench?

The ratchet of a wrench should be inspected for wear, cleaned and lubricated. Periodically verify that ratchet screws are tight and that the ratchet spins freely when turned. The wrench handle should not be loose and it should be free of corrosion or lubricants when used.

What is a torque wrench and how does it work?

A torque wrench is a tool used to apply a specific torque to a fastener such as a nut, bolt, or lag screw. … It allows the operator to set the torque applied to the fastener so it can be matched to the specifications for a particular application. This permits proper tension and loading of all parts.

How much does it cost to calibrate a torque wrench?

WRENCHES & SCREWDRIVERS Single Direction – Preset (For pneumatic & electric tools, add an additional 50%) ANSI-Z540 CW Rush Service*

——————————————————————————————————— ———— ————-

0 – 50 lbf.ft $50 + $75

51 – 250 lbf.ft $75 + $75

251 – 1,000 lbf.ft $100 + $150

1,001 – 2,500 lbf.ft $180 + $150

How does a torque driver work?

A torque screwdriver is a screwdriver with components that ensure tightening to a specified torque, ensuring tightening which is sufficient, but not excessive. … All have a torque-limiting clutch that disengages once the preset torque has been reached.

What happens if you dont use a torque wrench?

Not tightenough and it will work loose, and then you know to do it a bit tighter next time. However wheels and brakes are not hard to do without a torque wrench, so a lot comes down to what maintenance you will be doing and how much your bike is worth. Too tight is probably better than not tight enough!Sep 23, 2010

How do you calibrate a click type torque wrench?

Hang the loop end of the rope on your torque wrench where you made your mark in step one (15 inches for us) so that the weight is now suspended. If your torque wrench clicked once, the weight was applied, then set it to 26 foot-pounds. If it did not click, then your torque wrench is accurate already.

Do all torque wrenches click?

Some have a dial to set the required torque, but the indicator doesn’t stop applying force automatically when torque is reached. They may have a visual signal such as a digital reading or an audible beep or click. … A click torque wrench can be preset to a specific torque level.

What are the three types of torque wrenches?

There are four basic types of torque wrenches, each with slightly different operating principles: beam or deflection, dial indicator, clicker, and digital.

What are the best torque wrenches?

Torque Wrench Price

——————————— ———————– —–

Best clicking-style torque wrench Lexivon ½-inch drive $56

Best digital torque wrench Gearwrench ½-inch drive $116

Best beam-style torque wrench Tooluxe ½-inch drive $24

Best overall torque wrench Tekton ½-inch drive $40

How do you calibrate a torque wrench?

Is a torque wrench really necessary?

If you plan to do any major work on your engine or on some major powertrain components, you absolutely need a torque wrench. Overtightening cylinder-head bolts, for instance, can easily cause expensive damage and catastrophic coolant loss. Too-tight exhaust manifold bolts can cause the manifold to crack.

How do you use a torque wrench step by step?

Don’t forget to share this post 💖

References and Further Readings :