Crankshafts are made from forged steel or cast iron. Crankshafts for high-volume, low-load production vehicles are generally constructed from nodular cast iron, which has high strength (see Appendix D). Fuel-efficient engines require a high power-to-displacement ratio, which has increased the use of forged crankshafts.

Thereof, Does a crankshaft add horsepower?

For a big block Chevy, Ford or Chrysler motor, a stock crank can usually handle up to 550 hp. But beyond that, a stronger performance crank is needed to handle the additional power. … Engine speed is also a critical factor in crankshaft loading.

Also to know is, Are Eagle crankshafts any good? All in all, Eagle does have some flaws, but they do make a pretty good product for what you paying for it. As for the cast cranks, some of them are pretty rough, but they are designed for mild performance. I got what I payed for LOL.. 😆 The crankshaft still sits in my garage. Works excellent for a doorstop.

Subsequently, question is, What is best a forged crankshaft vs Steel? Cast steel is stronger due to the fact that steel is stronger than iron. … Like cast pistons, there is less finish machining to do so they cost less. With forged steel cranks, a metal bar is heated until it is soft then pounded into the rough shape of the crankshaft. From there it is machined into the final shape.

Also, What are the methods and materials used in the manufacture of crankshafts?

There are mainly three processes which are used for crankshaft manufacturing for metals: forging, casting, and machining. Forging is nothing but shaping of metal by plastic deformation. There are three typical stages of crankshaft forging.

How can you tell if a crankshaft is forged?

The best and most sure method for recognizing a forged crank is to look for the parting lines on the counterweights. A forged piece will have a wide, irregular rough patch. A cast component (shown) will have a very sharp, well-defined line where the mold was separated.

Is a forged crankshaft necessary?

Yes they are in many incidences. Forged steel cranks are the way to go if you’re building a hot street performance, or an all out racing engine. Many factory engines came with forged cranks.

Does boring an engine increase horsepower?

Boring an engine involves using machines to widen and taper the cylinders. From a performance standpoint, boring an engine could give you more horsepower and torque, as it will change the engine’s displacement. In general, the greater your engine’s displacement, the more power it can create. …

How do you know if your engine needs boring?

Check the bores – if one or more are damaged, scored or heavily pitted, then it will need boring. light scratches and surface rust can be dealt with by honing, without the need for a full rebore.

How strong is a cast steel crankshaft?

Most cast iron crankshafts have a tensile strength in the 65,000-80,000 psi range.

What is the strongest crankshaft?

At the very top of the food chain are billet steel crankshafts. These cranks start as a solid bar of high-grade steel and are then carved and machined into the final crankshaft shape. Because of the machining process, these are considered by many as the strongest crankshafts and are often not given rated power limits.

What is better forged or cast crankshaft?

Cast steel is stronger due to the fact that steel is stronger than iron. … Like cast pistons, there is less finish machining to do so they cost less. With forged steel cranks, a metal bar is heated until it is soft then pounded into the rough shape of the crankshaft. From there it is machined into the final shape.

What steel are crankshafts made from?

Crankshafts are made from forged steel or cast iron. Crankshafts for high-volume, low-load production vehicles are generally constructed from nodular cast iron, which has high strength (see Appendix D). Fuel-efficient engines require a high power-to-displacement ratio, which has increased the use of forged crankshafts.

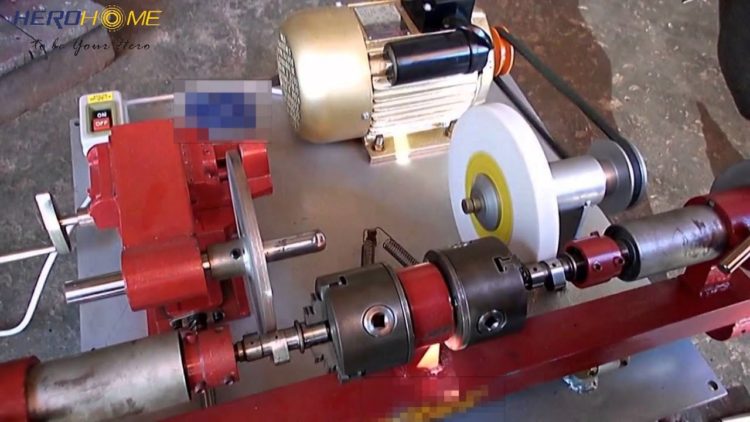

How do you make a crankshaft?

How are crankshafts manufactured?

Forging and casting, and machining Crankshafts can be forged from a steel bar usually through roll forging or cast in ductile steel. Today more and more manufacturers tend to favor the use of forged crankshafts due to their lighter weight, more compact dimensions and better inherent damping.

Where are Eagle crankshafts made?

China

How are crankshafts forged?

A forged steel crank is manufactured by compressing a much purer metal into the die under extreme heat and pressure to create a very dense molecular structure…and a much stronger crank. It’s relatively easy to spot the difference between a cast crank and a forged one.

Don’t forget to share this post 💖

References and Further Readings :