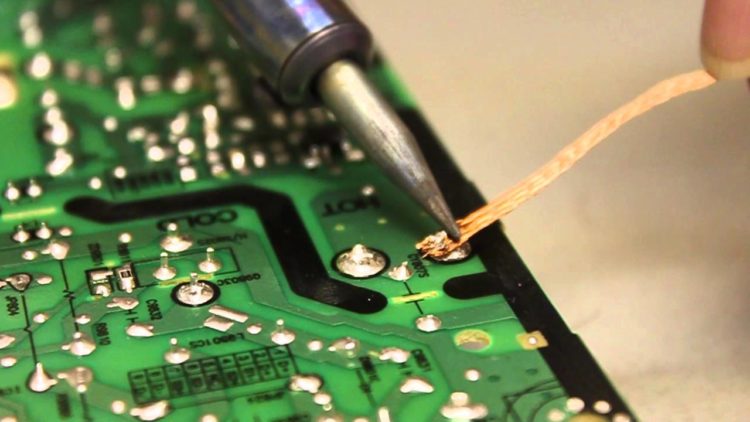

– Place the braid over unwanted solder, preferably on the greatest solder build up so that it maximizes the contact of the braid to the surface area of the solder.

– Next, place your iron tip over the wick at 45 degrees and allow heat to transfer to the pad.

To use solder wick, simply place the end of the wick over the solder you want to remove and then place your heated solder tip over it. The braid heats up and encourages the solder to “wick” into it. When it starts to work, you will actually be able to see the solder being pulled up into the solder wick.

Thereof, How do you use a desoldering braid?

Also to know is, Does flux help Desolder? 2 Answers. Flux’s job is to clean copper by removing impurities so that solder can properly wet (think “adhere”). When desoldering, you should apply flux to whatever the solder is supposed to wet to. If you are using a copper desoldering braid, then apply a bit of flux to it.

Subsequently, question is, How do you use a solder wick? To use solder wick, simply place the end of the wick over the solder you want to remove and then place your heated solder tip over it. The braid heats up and encourages the solder to “wick” into it. When it starts to work, you will actually be able to see the solder being pulled up into the solder wick.

Also, Can you solder in cold weather?

You can solder in cold temps, but you have to have a soldering iron that compensates.

How do you use a solder removal braid?

Place the exposed desoldering braid over the solder joint on the circuit board that you want to desolder. Press down on top of the desoldering braid with your soldering iron until you see and/or feel the solder beneath the braid start to liquify and flow.

How do you remove solder without heat?

Touch the cold flat head screwdriver to the liquid solder, and quickly remove it. If done properly, the solder should adhere to the cold screwdriver and can be removed from the surface. This process can be repeated to remove any remaining amount of solder.

How do you do desoldering?

Is there such a thing as cold solder?

A Cold Heat soldering iron is a tool that seems to break the rules of soldering. As with other soldering irons, it melts solder — an alloy that softens at a low temperature and hardens as it cools. … But while most soldering irons plug into a wall outlet, the Cold Heat tool uses batteries.

How do I keep my solder joints cold?

The way you repair a cold joint is by reheating it with your soldering iron until the solder begins to flow. Cold joints frequently have excess solder which you can draw off with the soldering iron tip. You can prevent cold solder joints by giving your soldering iron sufficient power and time to warm up.

How do you use solder remover?

What does a solder wick do?

Desoldering braid or “wick” is a pre-fluxed copper braid that is used to remove solder, which allows components to be replaced and excess solder (e.g. bridging) to be removed.

How do you remove stubborn solder?

– The printed circuit board is held in a vise or PCB holder.

– The tip of the desoldering bulb is placed behind the hole and the bulb is squeezed.

– The tip of a heated soldering iron is pressed against the hole to melt the solder.

Is there such a thing as liquid solder?

Liquid solder is a heavy-duty, water-resistant, and strong adhesive that will keep the components properly bonded to the board. Like solder pastes, liquid solder for circuit boards contain metals that will help create a conductive joint between metal surfaces to establish an electrical connection.

How do you keep solder joints from drying out?

Ensure that the items to be soldered are secured so that they will not move in the soldering process as this can result in a dry joint. Tin the tip of the soldering iron, wipe it clean on a damp spongue and then add a small amount of solder again – this helps the heat to flow onto the joint quickly.

What does flux do when your soldering?

The flux also protects the metal surfaces from re-oxidation during soldering and helps the soldering process by altering the surface tension of the molten solder. Flux is made up of a base material and an activator which is the chemical that promotes better wetting of the solder by removing oxides from the metal.

What does cold solder look like?

A cold solder joint occurs when the solder does not melt completely. A result of insufficient heat, cold joints are often characterized by being rigid, rough, and uneven in appearance.

Don’t forget to share this post 💖

References and Further Readings :